In modern packaging operations, battery life is crucial for productivity and cost-efficiency. A battery-powered strapping tool with a long-lasting battery means fewer interruptions, less downtime, and smooth operations in demanding work environments. When tools need frequent charging, it disrupts the workflow—workers lose focus, packaging lines slow down, and labor costs increase.

This 2025 buyer guide is designed for procurement managers, warehouse supervisors, and packaging professionals. It provides valuable information on how to choose battery-powered strapping tools with the longest battery life. In this guide, you will learn about:

- How battery capacity and motor efficiency affect real-world performance

- Important features that set high-endurance tools apart from standard models

- Evaluation criteria tailored to your specific packaging volume and operational needs

- Maintenance strategies to keep batteries healthy and extend tool lifespan

The right battery strapping solution enables your team to maintain consistent packaging quality while maximizing the value of your equipment investment.

Mastering Battery-Powered Strapping Tools

A battery operated strapping tool is a cordless device used to tighten and seal plastic or polyester straps around packages, pallets, and bundled products. Unlike manual or pneumatic systems, these advanced tools offer complete freedom of movement in warehouses and production areas.

The battery powered bander automatically tightens the strap to a set tension level, then uses heat or friction to bond the strap ends together securely.

Key Features of Battery powered strapping tools

Modern battery-powered strapping tools have several features that set them apart from manual or pneumatic tools:

- Adjustable tension settings: Operators can customize the strap tightness based on package needs (usually between 10 to 60 kg of tension force).

- Automatic sealing mechanisms: The strapping process finishes without any manual help.

- Ergonomic handles and balanced weight distribution: These design elements reduce operator fatigue during long periods of use.

- Compact, portable design: The tools are small and easy to carry, allowing for operation in tight spaces with one hand.

Versatility and Compatibility

These tools are versatile as they can work with both PET (polyester) and PP (polypropylene) strapping materials in different widths, typically ranging from 9mm to 19mm.

Advantages of Brushless Motor Technology

Premium models of battery-powered strapping tools feature brushless motor technology, which offers several advantages over traditional brushed motors:

- Improved efficiency

- Longer lifespan

- Minimal maintenance requirements

This motor design generates less heat, reduces friction, and eliminates the need for periodic brush replacement found in older tool versions.

Key Benefits of Using Battery-Powered Strapping Tools for Packaging

Battery-powered strapping tools offer significant advantages that directly affect operational metrics and workplace conditions. The transition from manual methods to automated battery systems revolutionizes packaging operations in various ways.

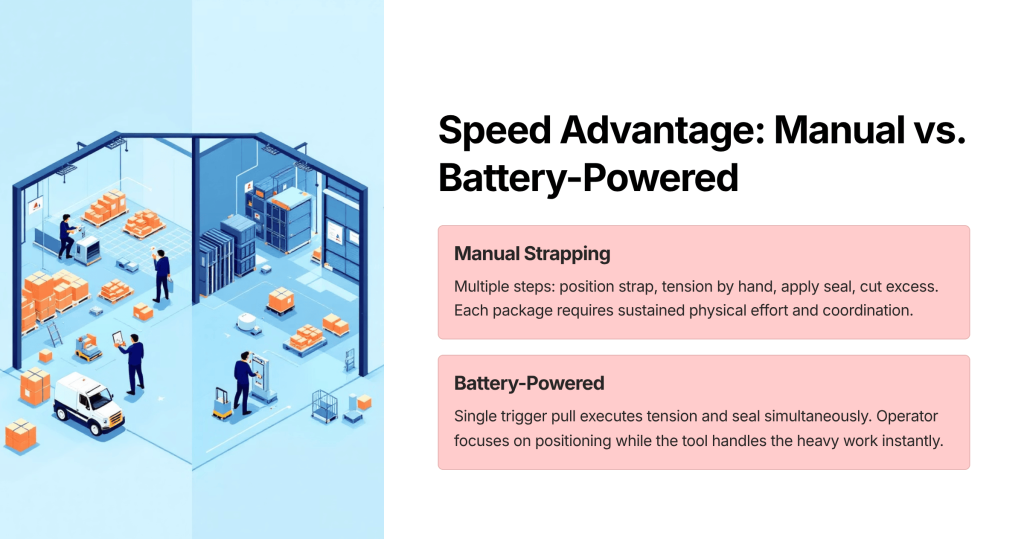

1. Enhanced Packaging Speed

Automated tensioning and sealing mechanisms enable operators to complete strapping cycles in seconds rather than minutes. Where manual tools require physical effort to tension each strap and apply separate seals, battery-powered units execute both functions in a single trigger pull. High-volume facilities report throughput increases of 300-400% when transitioning from manual to battery-powered systems, allowing the same workforce to process significantly more packages per shift.

2. Precision and Reliability

Programmable tension settings ensure each strap applies identical force, eliminating the variability inherent in manual operations. This consistent tension prevents both under-tensioning (which compromises load security) and over-tensioning (which can damage products or cause strap breakage). The automated sealing process creates uniform friction welds or crimps that maintain integrity throughout shipping and handling.

Prevents Under-Tensioning

Prevents Over-Tensioning

Quality Assurance

3. Worker Safety and Ergonomics

The physical demands of manual strapping—repetitive pulling, bending, and applying force—contribute to musculoskeletal disorders and workplace injuries. Battery-powered tools reduce these risks by automating the most strenuous aspects of the process. Operators maintain neutral postures while the tool performs the heavy work, decreasing fatigue during extended shifts and lowering injury-related costs.

The Critical Role of Battery Life in Strapping Tools' Performance

Battery capacity directly determines how many strapping cycles operators can complete before requiring a recharge, making it a fundamental specification when evaluating battery strapping tool options. The relationship between battery life and operational efficiency becomes particularly evident in high-volume environments where downtime for charging translates to measurable productivity losses.

Understanding Battery Capacity

Modern rechargeable lithium-ion batteries in strapping tools typically range from 2.0 Ah to 5.0 Ah capacity, with higher ampere-hour ratings delivering extended runtime. A 4.0 Ah battery system, for instance, can power between 300–400 strapping cycles per full charge under standard operating conditions, though actual performance varies based on strap tension settings, material thickness, and ambient temperature. Tool efficiency plays an equally significant role—brushless motor technology consumes less power per cycle compared to brushed alternatives, effectively extending the operational window between charges.

Importance of Charging Infrastructure

Charging infrastructure considerations prove equally important in the Top Battery-Powered Strapping Tools with the Longest Battery Life: 2025 Buyer Guide. Contemporary fast-charging systems restore batteries to full capacity in 15–30 minutes, enabling quick turnaround during shift changes or breaks. Some operations benefit from maintaining multiple battery packs in rotation, ensuring continuous availability while depleted units recharge. This approach eliminates waiting periods and maintains consistent workflow momentum throughout demanding production schedules.

Spotlight on Fromm's P329S Battery-Powered Strapping Tool: A Leader in Battery Life

The Fromm P329S stands out as one of the best battery-powered strapping tools available today. What sets it apart is its excellent engineering and impressive battery life. This tool features a highly efficient brushless motor that not only provides consistent power but also reduces energy consumption—a crucial advantage for tasks that require long-lasting performance during extended work shifts.

Key Features

Here are some key features that make the Fromm P329S a top choice:

- Powerful Motor: The brushless motor technology ensures reliable performance without the need for frequent maintenance.

- Long Battery Life: With its standard 4.0 Ah lithium-ion battery system, this tool offers enough power to complete demanding tasks without interruptions.

- Balanced Design: The battery configuration is designed to maintain an even weight distribution, making it comfortable to use for long periods.

- Versatile Compatibility: The P329S can work with both PET and PP strapping materials, accommodating widths ranging from 12mm to 19mm.

Real-World Performance Metrics

Field testing has shown that the P329S consistently delivers impressive results:

- 500-600 straps per full charge under normal operating conditions with 12-16mm PET strapping

- Maintained tension consistency throughout the entire battery discharge cycle

- Rapid cycle times averaging 2.5-3 seconds per strap application

- Reliable sealing performance even as the battery charge decreases

This combination of versatility and exceptional battery endurance makes the P329S particularly valuable for high-volume packaging environments where downtime directly impacts productivity and operational costs.

How to Choose the Best Battery-Powered Strapping Tool for Your Needs in 2025

Selecting the right battery-powered strapping tool requires careful analysis of your operational requirements. Begin by calculating your daily packaging volume—facilities processing 500+ packages per shift should prioritize tools offering 400+ strapping cycles per charge to avoid mid-shift battery swaps. Motor type significantly influences both performance and longevity; brushless motors deliver superior efficiency, generating less heat while extending battery runtime by up to 30% compared to brushed alternatives.

Examine adjustable tension settings to ensure compatibility with your strap materials and package types. Tools offering precise tension control (typically 10-60 kg range) prevent product damage while maintaining secure loads. Battery capacity matters: 4.0 Ah systems provide the sweet spot between weight and runtime, though high-volume operations may benefit from 5.0 Ah options despite the added heft.

Consider these critical factors:

- Strap compatibility: PET, PP, or both

- Seal method: Friction weld vs. heat seal

- Tool weight: Balance between battery capacity and operator comfort

- Charge time: 15-30 minute fast-charge capability for continuous operations

Industry Applications Suited for Battery-Powered Strapping Tools with Long Battery Life

Battery-powered strapping tools with extended runtime capabilities have become essential in various operational settings. Here are some industries that benefit from these tools:

1. Logistics Industry

The logistics industry heavily relies on battery-powered strapping tools for securing palletized shipments in distribution centers. With hundreds of loads requiring strapping every day, these tools play a crucial role in streamlining operations.

2. Warehousing Solutions

Warehousing solutions benefit from the portability and consistent performance delivered by battery-powered strapping tools. By eliminating the need for pneumatic infrastructure, these tools enable high throughput during order fulfillment and inventory management.

3. Manufacturing Facilities

Manufacturing facilities utilize long-lasting battery strapping tools on production lines where continuous operation is critical. This ensures efficient packaging processes without interruptions.

4. Food & Beverage Sector

The food and beverage sector demands reliable package security for various products, including bottled goods and bulk ingredient containers. Battery-powered strapping tools capable of handling multiple shifts without frequent recharging meet this requirement effectively.

5. Construction Sites

Construction sites particularly value the cordless freedom provided by battery-powered strapping tools. These tools offer flexibility when securing building materials, lumber bundles, and heavy equipment during transport.

The Top Battery-Powered Strapping Tools with the Longest Battery Life: 2025 Buyer Guide addresses the specific needs of these industries, recognizing that each sector has unique volume demands and environmental conditions influencing tool selection.

Maintenance Tips to Maximize Battery Life and Tool Performance

Proper maintenance routines directly influence both battery longevity and tool reliability.

Charging Best Practices

Charging best practices form the foundation of battery care:

- Avoid depleting lithium-ion batteries below 20% capacity before recharging, as deep discharges accelerate degradation.

- Store batteries at room temperature (15–25°C) when not in use.

- Remove batteries from chargers once fully charged to prevent overcharging stress.

Battery Care Tips

Battery care tips extend beyond charging protocols:

- Clean battery contacts monthly using a dry cloth to ensure optimal electrical connection.

- For tools with brushed motors, inspect carbon brushes every 500 cycles and replace them when worn below manufacturer specifications.

- Brushless motor models require less frequent intervention but benefit from periodic inspection of cooling vents for dust accumulation.

Mechanical Component Maintenance

Mechanical components demand attention as well:

- Sealing units: Remove debris and adhesive residue after every 100 straps using manufacturer-approved cleaning solutions

- Tension wheels: Inspect for wear patterns and replace when surface irregularities appear

- Feed mechanisms: Lubricate moving parts quarterly with recommended oils to maintain smooth operation

Document maintenance activities to identify patterns and schedule preventive interventions before performance degradation occurs.

Conclusion

Choosing the best battery-powered strapping tools requires careful consideration of your specific operational needs. Battery capacity has a direct impact on daily productivity, so it’s important to evaluate your packaging volume and determine if 300, 400, or more strapping cycles per charge will meet your workflow requirements. Look for models with brushless motor technology and durable batteries (4.0 Ah or higher) to reduce downtime and increase your return on investment.

The Top Battery-Powered Strapping Tools with the Longest Battery Life: 2025 Buyer Guide highlights tools like the Fromm P329S that demonstrate an ideal balance of runtime, ergonomic design, and reliable performance. Tailor your tool choice to address industry-specific challenges—such as high-volume logistics operations or fluctuating manufacturing environments—in order to optimize productivity in 2025 and beyond.